Spacers and Standoffs: A Complete Guide to Materials and Applications

What Are Spacer and Standoff?

Spacer and standoffs are essential components in mechanical and electronic assemblies. Though often used interchangeably, they serve slightly different purposes. A spacer is typically a non-threaded piece designed to maintain a set distance between two components, while a standoff often includes internal or external threads, allowing it to fasten parts together while also creating space. These small components play a critical role in optimizing structure, alignment, and stability, especially in high-precision applications like PCB standoff usage and RF module assemblies.

Understanding the differences between spacer and standoffs is vital for product designers, engineers, and assembly specialists. The right selection ensures not only mechanical stability but also electrical insulation, vibration resistance, and long-term reliability. At Precision CNC machined parts & RF Assembly solutions, we provide a wide variety of high-tolerance standoff solutions tailored for industrial and electronics sectors.

Common Materials Used in Spacer and Standoffs

Choosing the right standoff materials is crucial for achieving optimal performance in specific applications. Spacer and standoffs are available in a variety of materials, each offering unique mechanical, electrical, and thermal characteristics.

1. Aluminum

Lightweight and corrosion-resistant, aluminum is ideal for electronic housings and aerospace components. It's a popular choice for both hex standoff and round standoff designs due to its strength-to-weight ratio.

2. Brass

Brass offers excellent electrical conductivity, making it suitable for PCB standoff applications where grounding is important. It's also resistant to wear and has a polished finish for aesthetic assembly components.

3. Stainless Steel

If high tensile strength and corrosion resistance are required, stainless steel is the top choice. It performs well in harsh industrial environments, and it is often used for spacer and standoffs in automotive and medical equipment.

4. Nylon

For non-conductive, lightweight needs, nylon spacers and standoffs are perfect. They offer good thermal resistance and are widely used in consumer electronics where insulation is essential.

To help engineers and designers make an informed choice, here's a comparative summary of the three most commonly used materials in industrial spacer and standoff applications:

Material Comparison Table

| Material | Key Properties | Ideal Applications | Considerations |

|---|---|---|---|

| Brass | - Excellent electrical conductivity - Corrosion-resistant - Polished finish - Moderate strength |

- PCB standoffs (grounding) - Aesthetic assemblies - Conductive fastening |

- Heavier than aluminum - More expensive - May require plating |

| Aluminum | - Lightweight - Good strength-to-weight ratio - Corrosion-resistant - Non-magnetic |

- Lightweight electronics - Aerospace housings - High rigidity needed |

- Lower electrical conductivity - May deform under high load |

| Nylon | - Non-conductive - Very lightweight - Resistant to heat and chemicals |

- Insulating spacers for electronics - Where electrical isolation is critical |

- Lower mechanical strength - May absorb moisture over time |

Quick Tip: When designing PCBs or selecting hardware for sensitive electronics, always balance mechanical needs with thermal and electrical performance. Brass works best for conductivity, aluminum for weight-critical builds, and nylon for insulation.

At Precision CNC machined parts & RF Assembly solutions, we specialize in machining all these standoff materials with tight tolerances and customizable dimensions to fit any design specification.

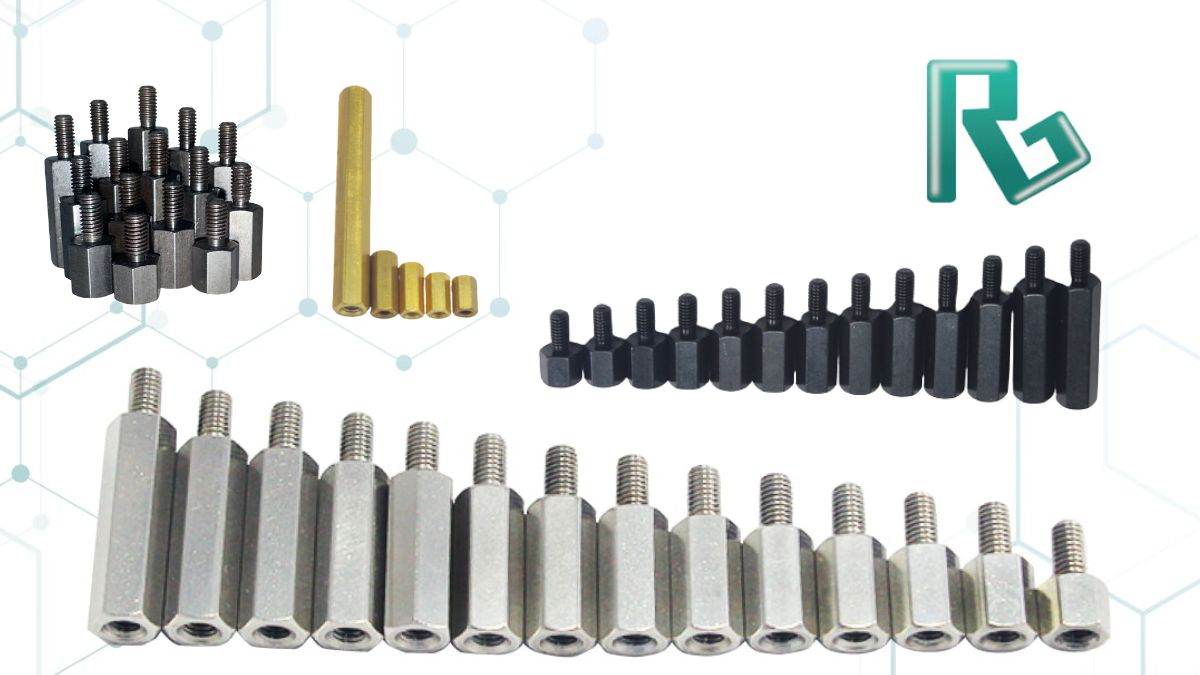

Types and Sizes: From Hex to M3 Standoffs

Spacer and standoffs come in many shapes and sizes, each suited for specific assembly requirements.

Hex Standoffs

The most common type, hex standoff, offers easy grip during manual installation and is available in male-female or female-female configurations. These are typically used in electronic hardware and control panels.

Round Standoffs

Round standoffs provide a cleaner look and are preferred in tight spaces or where aesthetic design matters. They are used in compact assemblies and decorative mounting applications.

M3 Standoffs

An M3 standoff refers to the metric thread size (3mm), widely used in electronics, especially for mounting PCB standoff components. M3 is a standard size for many development boards, embedded systems, and modular devices.

Knowing the right size and thread type is key to achieving both mechanical fit and electrical safety.

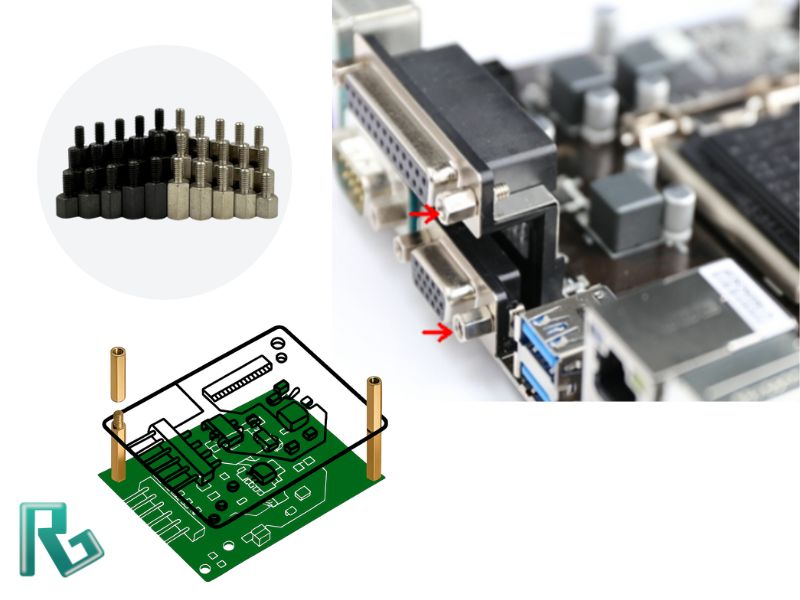

What Are Industrial Standoff Assemblies?

Industrial standoff assemblies refer to complete fastening setups involving standoffs, screws, washers, and PCBs. These are commonly found in telecommunications, automotive electronics, and industrial control boards.

How are Spacers and Standoffs Used?

Spacer and standoffs are indispensable in both consumer electronics and industrial machinery. Whether you're designing a compact device or a large-scale assembly, these components ensure proper alignment, prevent short circuits, and improve mechanical strength.

1. PCB Mounting

The most common use for a PCB standoff is to separate the printed circuit board from a metal or conductive surface, ensuring that electronic components don't short out. Standoffs also help with heat dissipation and airflow, which is critical in high-performance systems.

2. RF Module and Antenna Assemblies

In RF and wireless applications, spacer and standoffs ensure accurate spacing between circuit layers and shielding components. This precision directly affects signal integrity and electromagnetic interference (EMI) performance.

3. LED Displays and Control Panels

Standoffs are used to mount LED boards within enclosures, keeping them steady and reducing the risk of mechanical vibration. Nylon or brass options are typically preferred for aesthetic and insulating benefits.

4. Industrial Equipment

In high-vibration environments like motors or pumps, stainless steel hex standoff components are used to support panels, displays, or PCBs. They offer durability and high clamping force.

5. Aerospace and Automotive

In environments with extreme temperature changes, aluminum or stainless steel standoffs are used for weight savings and mechanical reliability.

With our commitment to precision and reliability, Precision CNC machined parts & RF Assembly solutions helps clients across industries integrate the best spacer and standoffs for their specific needs.

Industrial Market Insights for Spacers & Standoffs

With growing demand in electronics, telecommunications, and industrial assemblies, the global market for spacers and standoffs continues to expand. Choosing the right supplier and materials ensures reliability and cost efficiency in high-volume production.

Why Work with Precision CNC Machining Expert

At Precision CNC machined parts & RF Assembly solutions, we bring decades of experience in producing custom spacer and standoffs to exact specifications. Our CNC machining capabilities ensure tight tolerances, consistent quality, and rapid turnaround—whether you need a standard hex standoff or a complex PCB standoff configuration.

We understand the critical role these components play in modern product design. That’s why we offer engineering support, rapid prototyping, and full-scale production, ensuring every part fits perfectly into your system. Our materials range from high-performance plastics to aerospace-grade metals, tailored to your application’s exact demands.

Selecting the right spacer and standoffs involves understanding both material properties and application requirements. Whether you're working with PCB standoff configurations or rugged industrial applications requiring a hex standoff, choosing the right standoff materials will improve performance and longevity.

Partner with Precision CNC machined parts & RF Assembly solutions to access a full range of custom standoffs crafted to exact specifications. Contact us today to learn how we can support your next project with precision, performance, and professionalism.

📌 Frequently Asked Questions

❓ What’s the difference between a standoff and a spacer?

A spacer is a non-threaded component used to maintain distance between parts. It provides structural separation without securing the components.

A standoff, on the other hand, is threaded and not only maintains spacing but also allows components to be mechanically fastened together.

❓ Where are standoffs and spacers commonly used?

Standoffs and spacers are widely used in:

-

PCB (Printed Circuit Board) assemblies

-

Electronic enclosures

-

RF and communication modules

-

Medical and industrial equipment

-

Automotive electronics

They ensure proper component alignment, spacing, insulation, and vibration control.

❓ What materials are used for precision standoffs and spacers?

Common materials include:

-

Aluminum – lightweight and corrosion-resistant

-

Brass – electrically conductive and durable

-

Stainless steel – strong and corrosion-resistant

-

Nylon – lightweight and non-conductive

The material selection depends on the mechanical, electrical, and environmental requirements of your application.

❓ Do you offer custom manufacturing for standoffs and spacers?

Yes! We offer precision stand-offs manufacturing with options for:

-

Custom diameters, lengths, and thread sizes

-

Choice of materials and surface finishes

-

Threaded or non-threaded types

-

Low or high-volume production runs

Contact us to discuss your specific needs.

❓ How do I choose between a standoff and a spacer?

Choose a spacer if you need to separate parts without fastening them. Choose a standoff if you require secure mounting along with spacing. Also consider factors like load-bearing, threading requirements, and assembly method.

👉 View Our Black Oxide Spacer Bolts

---

Author: Materials & Metallurgy Expert|RunGu Enterprise Expert Team

Specialized in machining properties and surface finishing of metals.

About RunGu Enterprise Co., Ltd.

RunGu Enterprise Co., Ltd., based in New Taipei City, Taiwan, is a precision CNC machining manufacturer with nearly 30 years of experience. We provide one-stop customized solutions, including standoffs, RF coaxial connectors, pogo pins, shielding boxes, liquid cooling couplers, and other CNC metal components. Our products are widely used in electronics, telecommunications, medical devices, automotive, and industrial automation industries.

🌐 Learn more: Standoffs-tw

---